Parts

Custom Composite and Retrofit Parts

Solving your Retrofitting and Prototyping needs

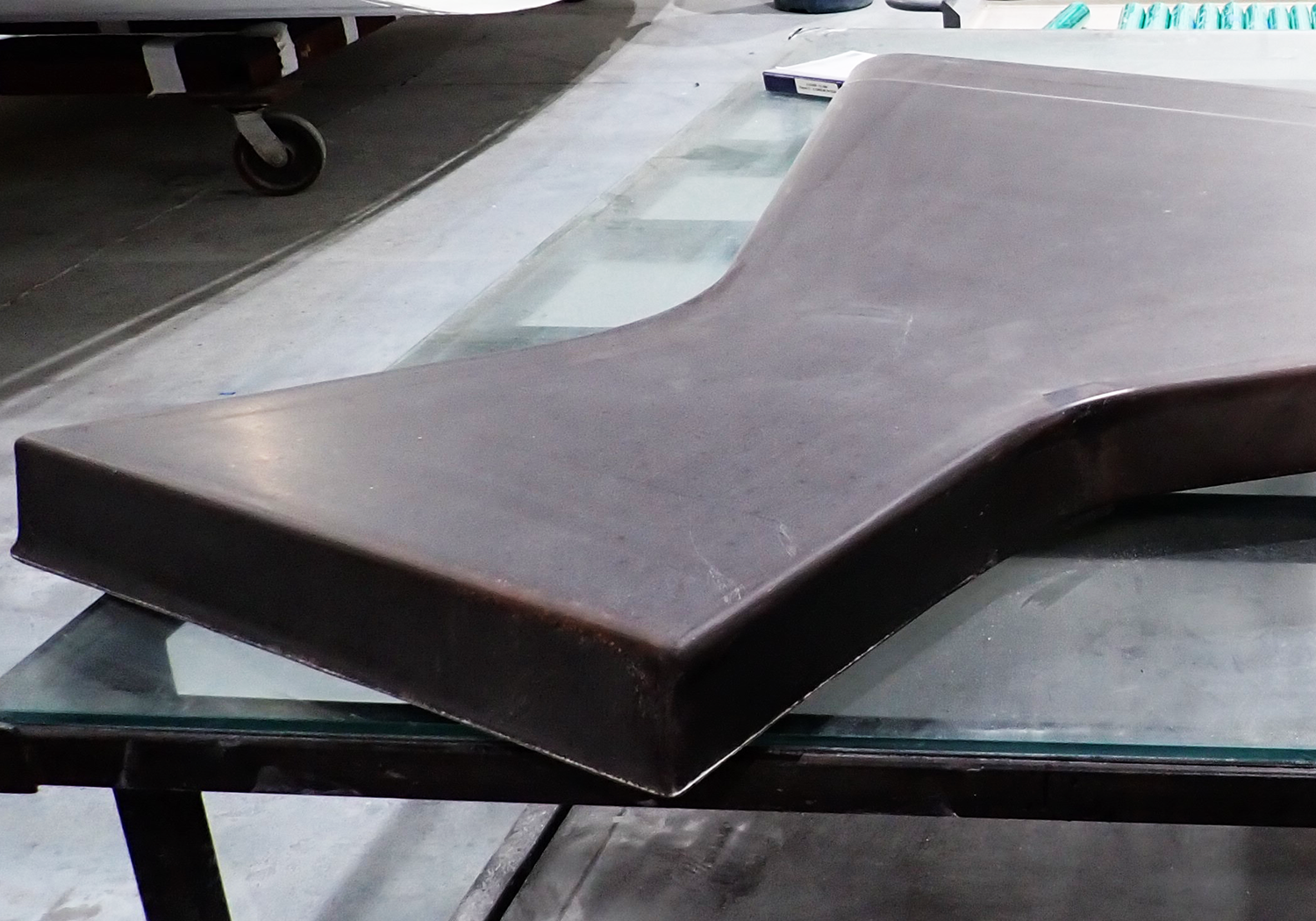

Whether you’re retrofitting an existing structure, building a prototype, or creating a single, specialized product, Janicki Marine can fabricate custom composite parts. Our tooling and part fabrication expertise ensures that you get exactly what you need with unparalleled precision and quality.

Our custom and retrofit composite parts fabrication services are designed for projects requiring one to five total parts. We build to print, creating single-unit parts using low-cost, direct-machined molds. Our processes accommodate both infused and laminated parts.

Custom Composite Parts, Retrofitting and Prototyping

Whether you’re retrofitting an existing structure, building a prototype, or creating a single, specialized product, Janicki Marine can fabricate custom composite parts. Our tooling and part fabrication expertise ensures that you get exactly what you need with unparalleled precision and quality.

Our custom and retrofit composite parts fabrication services are designed for projects requiring one to five total parts. We build to print, creating single-unit parts using low-cost, direct-machined molds. Our processes accommodate both infused and laminated parts.

Key Features of Our Composite Parts Services

- High-Accuracy Tooling: Low-temperature tooling is manufactured and machined in-house, with exceptional accuracy.

- Machine-Trimmed and Drilled Parts: Parts can be machine-trimmed and drilled, ensuring easy fit-up in final assemblies and reducing overall production time.

- Large-scale Manufacturing: We are equipped to handle large-scale parts, including those over 50 feet long and 16 feet wide.

Technical Specifications

- Parts are cured at 160°F or lower, ensuring compatibility with various applications.

- We achieve a typical surface profile accuracy of +/-.060”, providing you with parts that meet stringent quality standards.

- Our expertise includes working with vinyl esters and epoxies, and we offer a choice of materials based on your specific project needs.

Why Choose Janicki Marine?

Comprehensive Project Support

In-House Tool Design and Fabrication

Quality Promise

With years of experience in infusions and laminations, we uphold the highest standards of quality and craftsmanship. We ensure your parts meet or exceed requirements.

Let’s Build It Together

Our team of experts is ready to discuss your project.