Tooling

Production Tooling

High-Rate Boat Molds and Production Tooling

For high production-rate boat molds or marine production tooling programs, Janicki Marine offers several durable products depending on your project’s specific needs. Each product has a unique advantage for it’s application as outlined below.

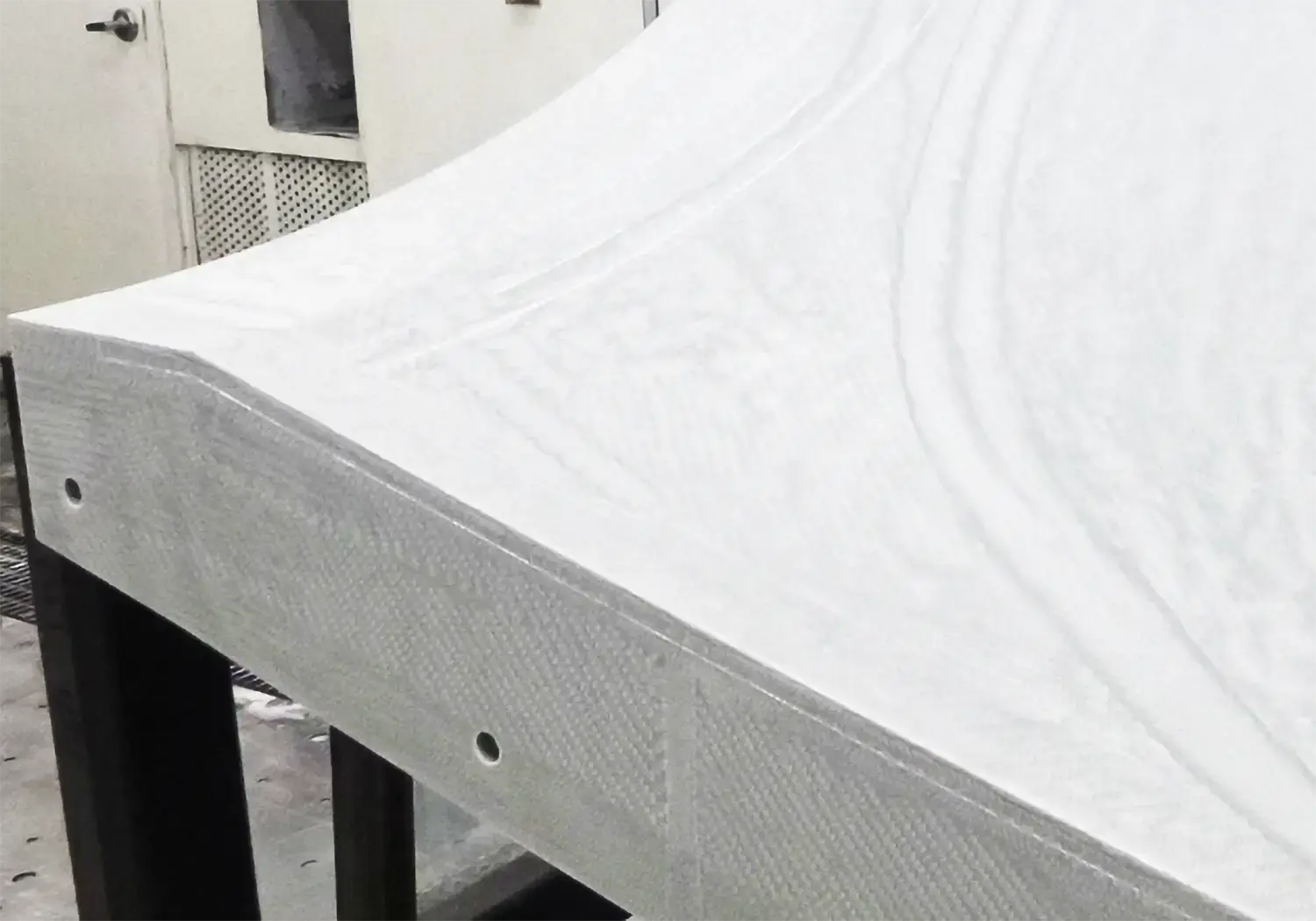

Machined Fiberglass Tooling

Our machined fiberglass tooling has a facesheet made of infused fiberglass epoxy, making them durable for many uses and higher cure temperatures. They offer a precise surface and are suitable for various complex shapes.

- Specifically designed for prepreg and infusion processing

- 275° F guaranteed temperature

- Can be built for tolerancing as tight as +/.020”

- Dimensionally stable steel frame with handling accommodations

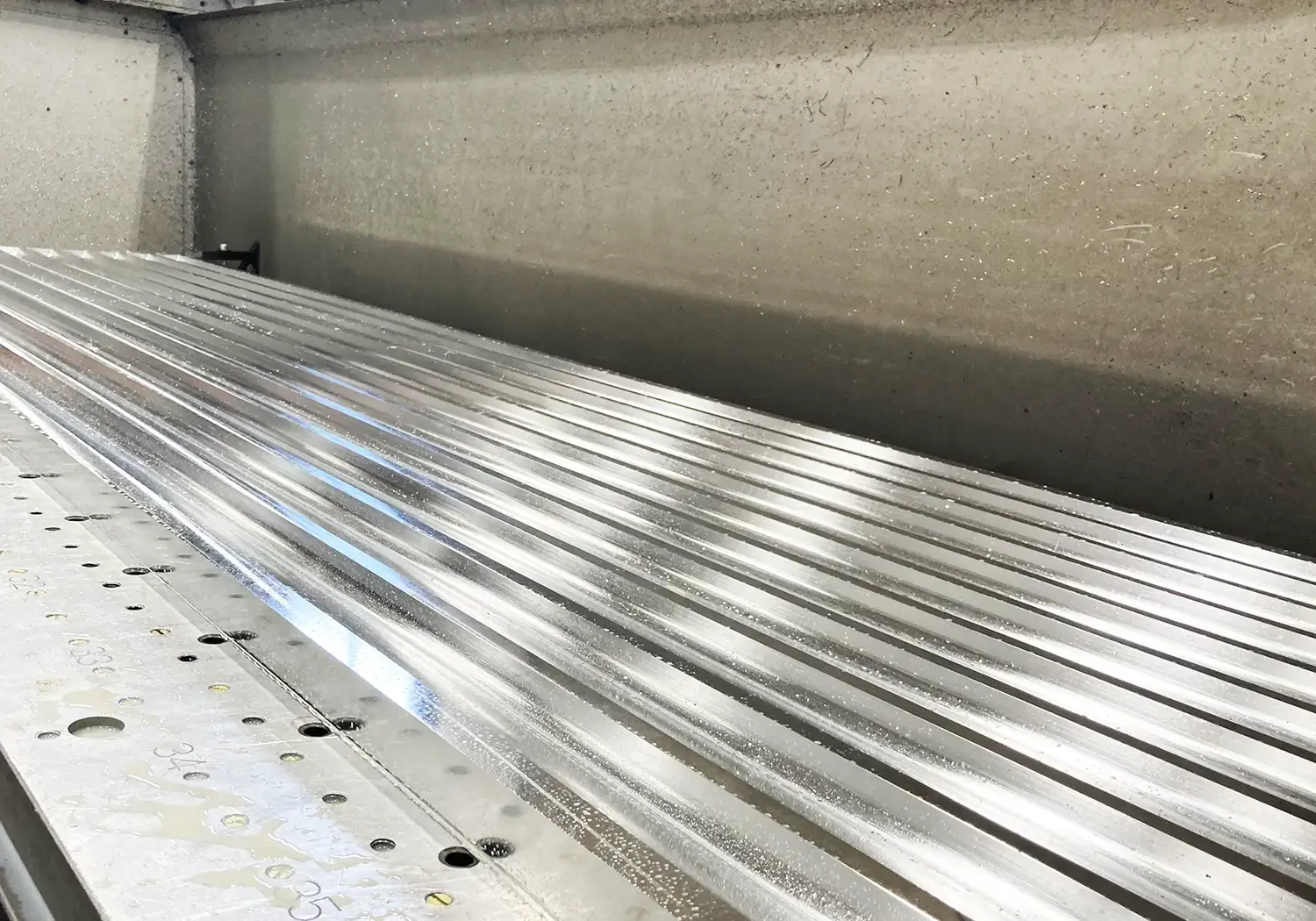

Machined Aluminum Molds

If your program requires a mold with a high level of accuracy and extreme longevity, our machined aluminum molds are a solid solution. Aluminum billets are machined and then mounted on a structure or fixture for easy mobility around the shop.

- Designed and built for a wide range of products

- Can be built for tolerancing as tight as +/.020”

- Suited for high-volume and long-term production of parts

- Excellent for highly complex parts or draft draft-locked geometry that requires inserts

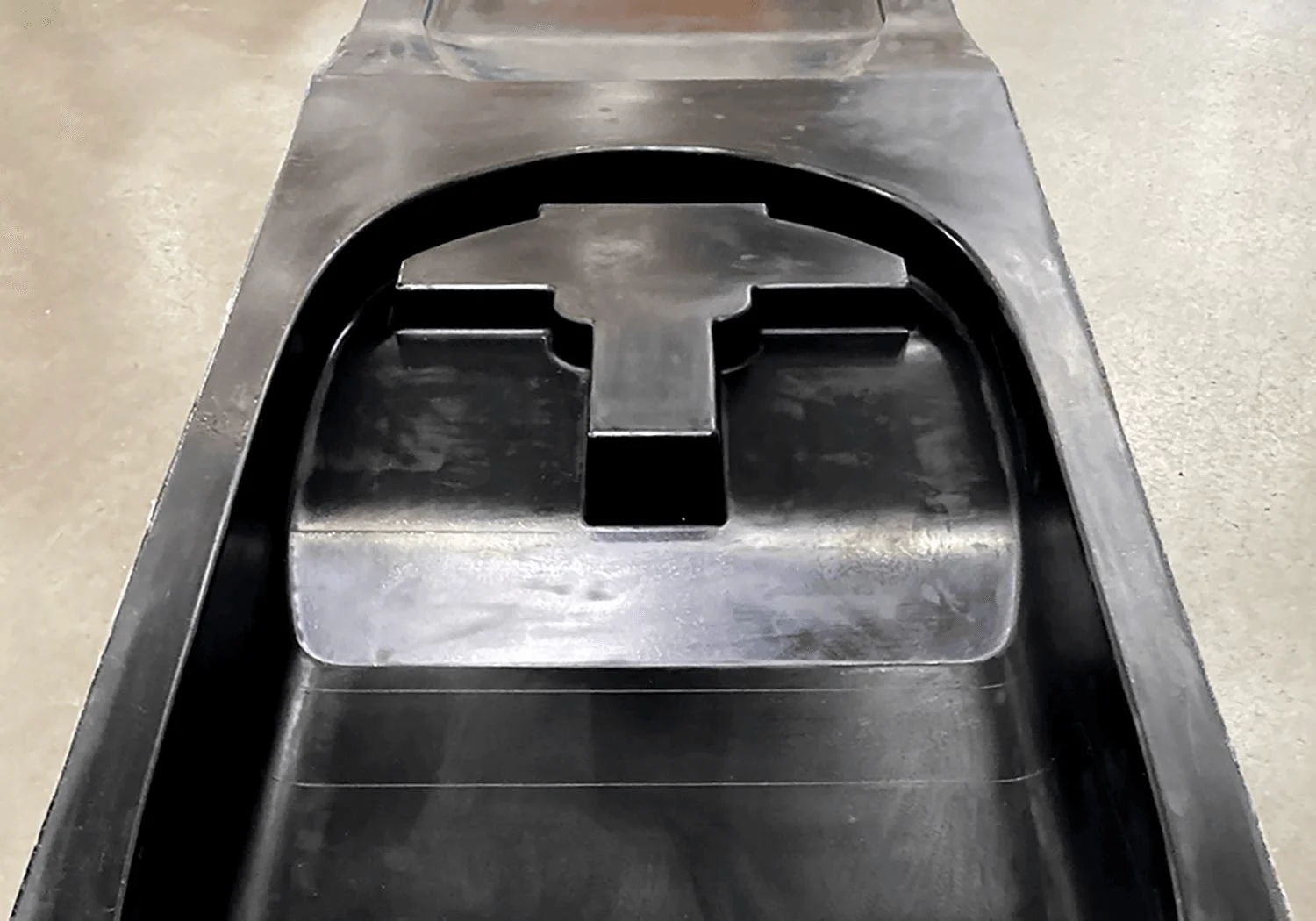

Cast Tooling

Cast tools are comprised of cast carbon or fiberglass face sheets supported with backing structures that can be easily moved around the shop. These facesheets are vacuum integral and rated for a use temperature per the requirements of the part resin matrix.

- Designed for infusion and prepreg parts processing

- Global tolerance as cast from an accurately machined master

- 200° F temp tooling

- Casters or fork tube accommodations on tooling

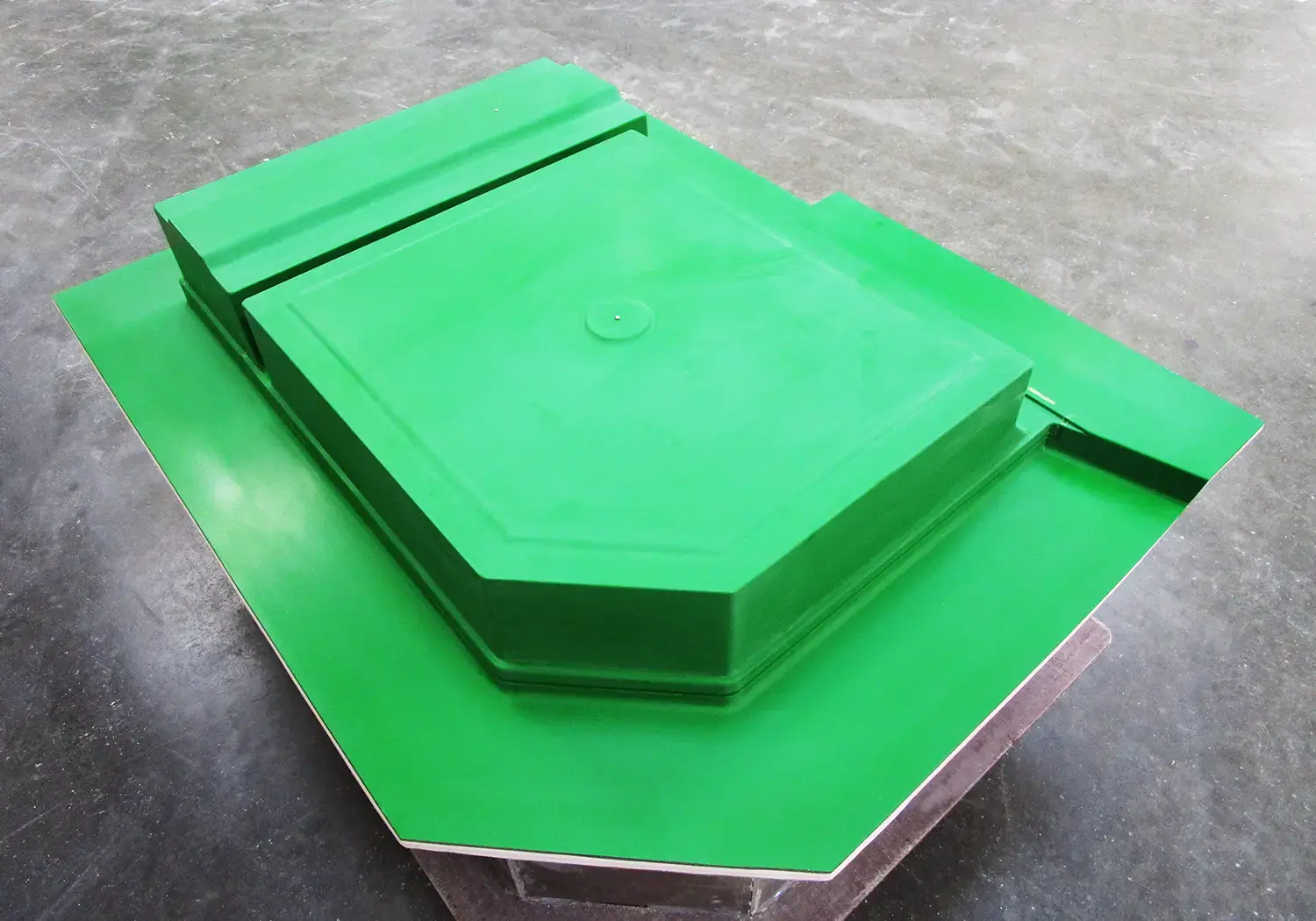

Gel Coat Tooling

Janicki’s Gel Coat tooling is designed with hard, durable, glossy surfaces required to produce high-finish products.

- Fiberglass facesheet

- 200° F temp tooling

- 200 + part cycles

- Trussed steel frame

Why Choose Janicki Marine?

Complexity Simplified

Quick Turnaround

By controlling every aspect of the production process in-house, we ensure seamless coordination and faster turnaround times. Our goal is to maintain your production timeline by delivering as scheduled.

Quality Promise

We Create Solutions

Choosing the correct tooling package doesn’t need to be confusing. Let’s discuss your program’s needs and create a custom production tooling solution.